- This project has technological innovation, large scale, good economic benefits, environmental contributions, and broad market prospects

- This project successfully converts coal, natural gas, or steel plant gas into ethanol, breaking the limitations of traditional production methods

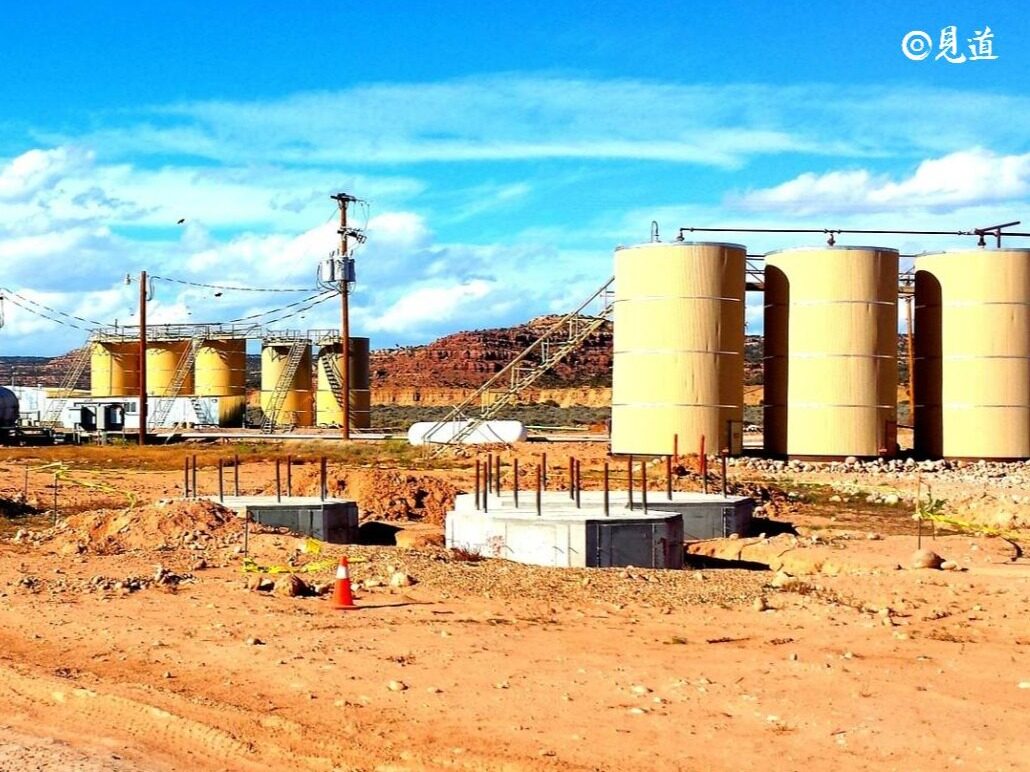

The world's largest 600000 tons/year ethanol production plant was put into trial operation on December 28, 2023, successfully producing high-quality anhydrous ethanol.

It is understood that the device adopts the advanced technology jointly developed by Dalian Institute of Chemical Physics, Chinese Academy of Sciences and Yanchang Petroleum Group. Its main raw material methanol comes from coke oven gas, which is converted to produce ethanol. The application of this technology not only significantly improves the added value of products, but also provides effective solutions for achieving low-carbon integrated development in industries such as steel and energy.

Liu Zhongmin, an academician of the CAE Member, believes that from the perspective of atomic economy, it is relatively easy to synthesize oxygenated compounds such as alcohol, ether, acid and other products through the coal chemical route. Ethanol, as one of these products, is an ideal target product. If coal gasification synthesis gas, coke oven exhaust gas, and steelmaking exhaust gas can be used to produce ethanol, then the problem of fuel ethanol shortage in China will be effectively solved. This will bring more green development opportunities for the coal chemical industry, steel industry, and coking industry.

Since 2010, the team of academician Liu Zhongmin of Dalian Institute of Chemical Physics, Chinese Academy of Sciences, has been committed to developing the synthesis technology of anhydrous ethanol. They proposed a process route for synthesizing anhydrous ethanol using syngas as raw material through dimethyl ether carbonylation and methyl acetate hydrogenation reaction. This route uses non precious metal catalysts to enable large-scale conversion of coal, natural gas, or steel plant gas into ethanol, with significant environmental friendliness. In 2017, Dalian Institute of Chemical Physics collaborated with Yanchang Petroleum Group to jointly develop DMTE process technology. This technology has successfully completed the world's first industrial demonstration project of producing ethanol through dimethyl ether carbonylation of 100000 tons/year of methanol, laying the foundation for the large-scale production of ethanol.

After developing DMTE technology, Academician Liu Zhongmin's team continuously iterated and upgraded the technology, optimized the catalyst and reaction process, further improved the technical indicators, and laid a solid foundation for large-scale industrial production of ethanol. Regarding the characteristics of DMTE technology, Academician Liu Zhongmin pointed out that this technology uses molecular sieve catalysts instead of expensive metal catalysts, adopts a multiphase catalytic system, makes the separation of reaction products simple, the reaction system non corrosive, and reduces the requirements for equipment materials.

The above characteristics of DMTE technology have brought it good economic benefits. After calculation, the cost of producing ethanol through grain fermentation in China is about 6500 yuan/ton, while the cost of producing ethanol through DMTE method is only about 4500 yuan/ton. In addition, based on methyl acetate and ethanol, ethyl acetate, acrylic esters, and other high value-added fine chemicals can also be produced.

The trial production unit constructed by Huaibei Mining Group Carbon Xin Technology Co., Ltd. has become the largest project of its kind in the world with an annual production capacity of 600000 tons. The device has been receiving much attention since its construction began on December 20, 2021. Academician Liu Zhongmin pointed out that the successful start-up of the pilot production of the device not only verified the progressiveness and reliability of DMTE technology, but also laid a solid foundation for the large-scale application of the technology. Keywords: engineering construction, engineering news, engineering construction information.

It is understood that DMTE technology has gained widespread recognition in the industrial production field due to its unique economic and environmental friendliness. As of now, 13 industrial device technology implementation license contracts have been signed for this technology, involving an ethanol production capacity of up to 3.95 million tons. (This article is from the official website of Jiandao: www.seetao. com. Reproduction without permission is not allowed, otherwise it will be punished. Please indicate Jiandao's website and the original link when reprinting.) Jiandao's mechanical column editor/Zhou Yingwen

Comment

Praise

Praise

Collect

Collect

Comment

Comment

Search

Search

Write something~